服务热线

13313705507

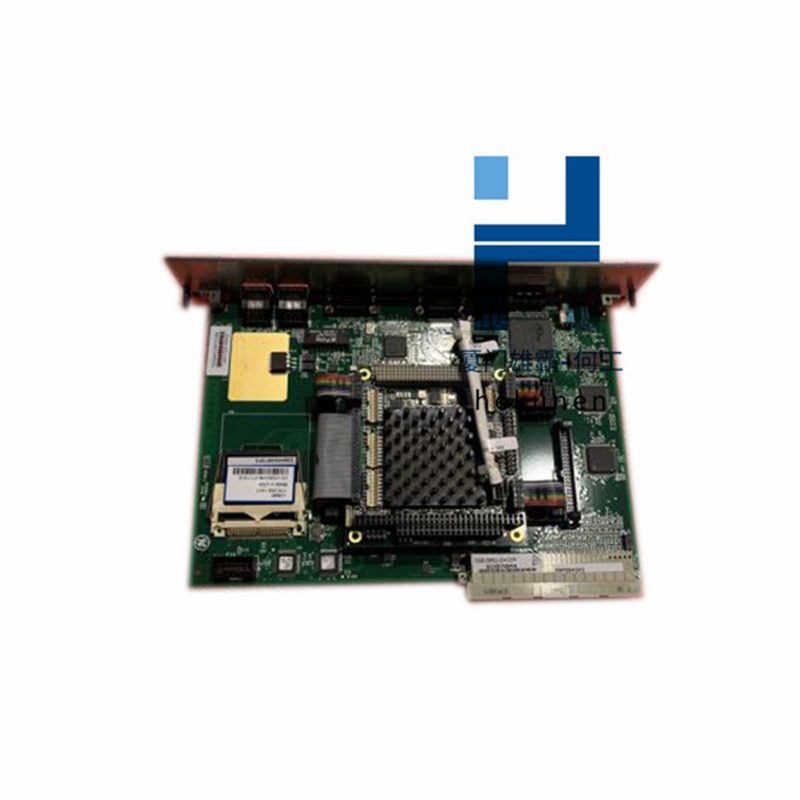

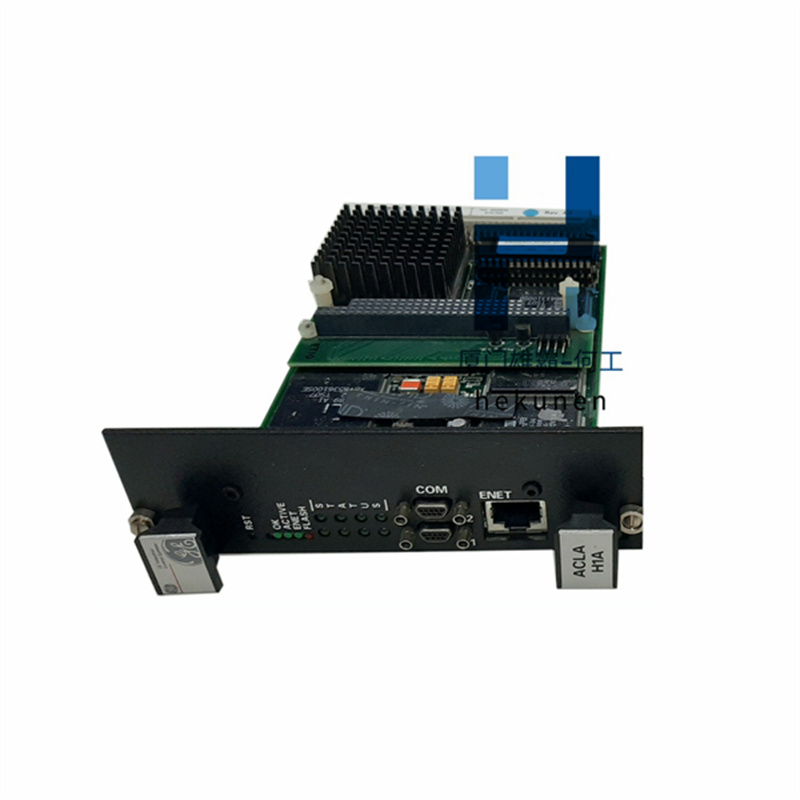

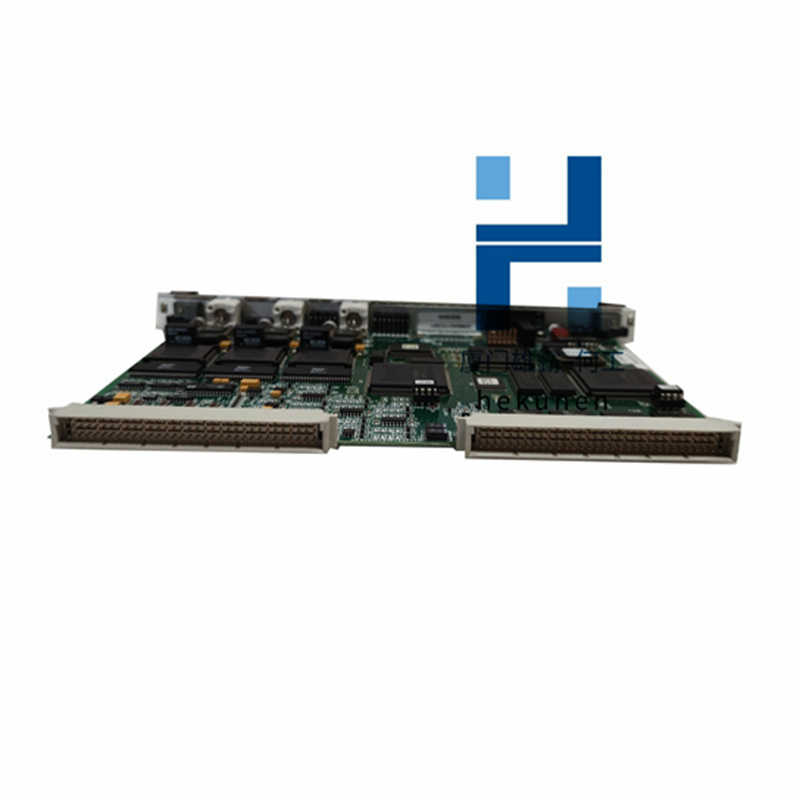

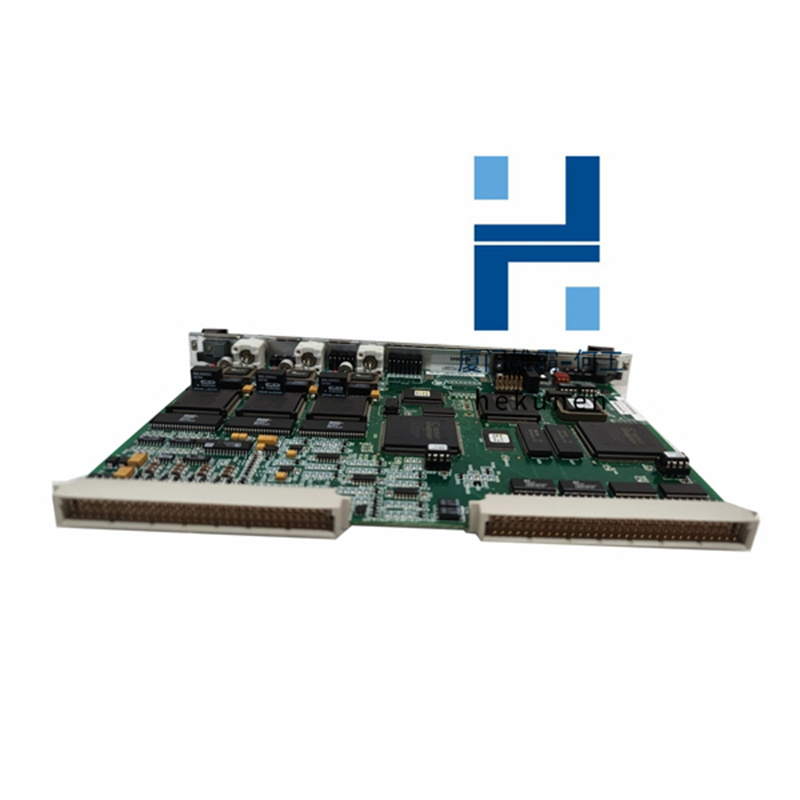

型号: GE IS215UCVEH2AE

分类: 通用电气 GE

联系人:何经理

手机:13313705507

QQ:2235954483

邮箱:2235954483@qq.com

地址:厦门市思明区吕岭路1733号万科创想中心2009室

直线电机是一种将电能直接转换为直线运动的机械能的电机,它不需要任何中间转换机构,如齿轮或滑块等。它可以看作是旋转电机沿径向剖开并展开成平面的形式。

直线电机驱动技术是近10年发展起来的新型进给传动方式,在高速、精密加工设备上具有广泛的应用前景。直线电机作为一种将电能直接转换成直线运动机械能的传动装置,具有起动推力大、传动刚度高、动态响应快等优点。

传统的旋转电机需要通过齿轮、皮带或其它传动机制将旋转运动转换为直线运动。这不仅增加了能量损失,还带来了机械磨损。直线电机直接将电能转换为直线运动,省去了这些中间步骤,提高了效率和可靠性。

由于没有机械传动链的限制,直线电机可以实现非常高的速度和加速度。这对于需要快速启停的应用场景尤为重要,例如工业自动化和高速运输系统。

直线电机的直接驱动特性使得它能够控制位置。这在数控机床等需要高精度的场合尤为重要。通过控制,可以实现更高质量的加工效果。

直线电机具有快速的动态响应能力,这使得它在需要频繁启停和速度变化的应用中表现出色。例如,在工业自动化生产线上,可以快速响应控制指令,显著提高生产效率。

传统的机械传动系统由于存在机械磨损,需要定期维护和更换零件。直线电机由于没有机械传动部件,显著减少了维护需求,降低了运营成本。

直线电机作为一种新型的电机技术,凭借其高效率、高精度和高响应性等优点,正在越来越多的领域中得到应用。特别是在高速列车、工业自动化和数控机床等领域,直线电机展现出了巨大的应用潜力和发展前景。随着技术的进一步发展,直线电机有望在更多的领域中发挥重要作用。

Linear Motor

concept

A linear motor is a type of motor that directly converts electrical energy into mechanical energy for linear motion, without the need for any intermediate conversion mechanisms such as gears or sliders. It can be seen as a rotating motor that is radially cut open and unfolded into a flat form.

characteristic

1. Direct drive: No mechanical transmission components, reducing energy loss and wear.

2. High speed and acceleration: Due to the lack of mechanical transmission chains, fast acceleration and high-speed movement can be achieved.

3. High precision: Due to direct drive, it can provide very precise position control.

4. High responsiveness: Fast dynamic response capability, suitable for applications that require quick start stop.

5. Maintenance free: No mechanical transmission components, reducing maintenance requirements.

Usage scenarios

1. High speed trains: Maglev trains using linear motors can achieve very high speeds.

2. Industrial automation: In automated assembly lines, linear motors can be used to move objects quickly and accurately.

3. CNC machine tools: In situations where high-precision machining is required, linear motors can provide precise cutting paths.

application prospect

Linear motor drive technology is a new type of feed transmission method developed in the past decade, which has a wide range of application prospects in high-speed and precision machining equipment. As a transmission device that directly converts electrical energy into linear motion mechanical energy, linear motors have advantages such as high starting thrust, high transmission stiffness, and fast dynamic response.

Detailed analysis

1. Direct drive

Traditional rotary motors require gears, belts, or other transmission mechanisms to convert rotational motion into linear motion. This not only increases energy loss, but also brings about mechanical wear. Linear motors directly convert electrical energy into linear motion, eliminating these intermediate steps and improving efficiency and reliability.

2. High speed and acceleration

Due to the absence of mechanical transmission chains, linear motors can achieve very high speeds and accelerations. This is particularly important for application scenarios that require fast start stop, such as industrial automation and high-speed transportation systems.

3. High precision

The direct driving characteristics of linear motors enable them to control the position very accurately. This is particularly important in situations such as CNC machine tools that require high precision. Through precise control, higher quality machining results can be achieved.

4. High responsiveness

Linear motors have fast dynamic response capabilities, which makes them excellent in applications that require frequent start stop and speed changes. For example, in industrial automation production lines, control commands can be quickly responded to, significantly improving production efficiency.

5. Maintenance free

Traditional mechanical transmission systems require regular maintenance and replacement of parts due to mechanical wear and tear. Due to the lack of mechanical transmission components, linear motors significantly reduce maintenance requirements and lower operating costs.

conclusion

Linear motor, as a new type of motor technology, is being applied in more and more fields due to its advantages of high efficiency, high precision, and high responsiveness. Especially in the fields of high-speed trains, industrial automation, and CNC machine tools, linear motors have shown enormous application potential and development prospects. With the further development of technology, linear motors are expected to play an important role in more fields.

如果您有任何问题,请跟我们联系!

联系我们