服务热线

13313705507

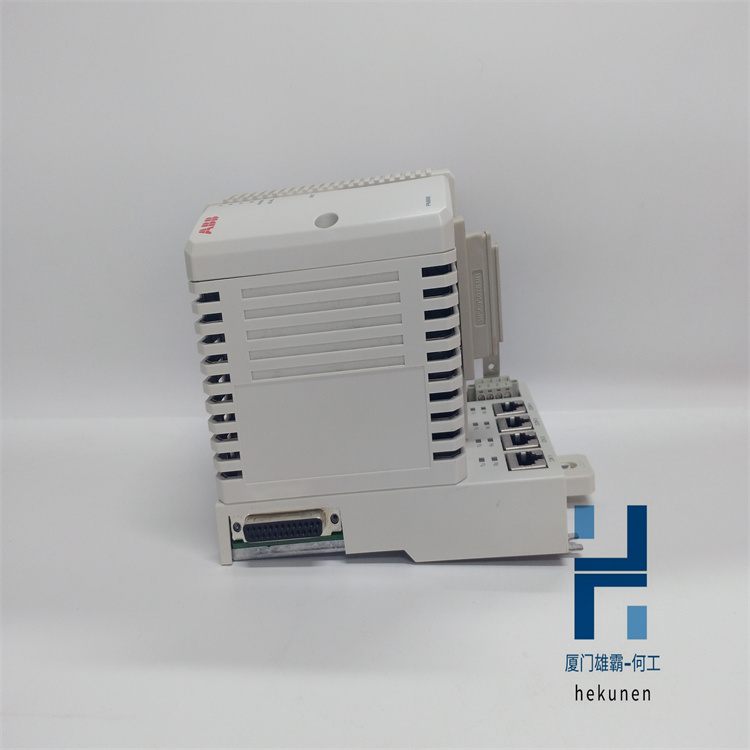

型号: PM633 3BSE008062R1

分类: ABB系统备件

联系人:何经理

手机:13313705507

QQ:2235954483

邮箱:2235954483@qq.com

地址:厦门市思明区吕岭路1733号万科创想中心2009室

无论是在城际铁路线还是市政公共交通系统中,都在金属轨道上运行,这些轨道需要始终保持直立并根据标准轨距适当间隔。如果铁轨变得不平坦,火车可能会脱轨。

这就是为什么用户总是看到某种支撑,称为铁路枕木或道碴,垂直放置在轨道下方。为确保平稳行驶,铁轨需要通过长钉、螺钉或螺栓牢固地固定在轨枕上。

由于快速移动的火车车轮与轨道之间的持续摩擦和振动,以及自然环境的破坏,轨道紧固件会随着时间的推移而退化和断裂。因此,及时检测和修复轨道扣件对于确保任何铁路线的安全都至关重要。

东亚的一条大型都市铁路需要一种更有效的方法来检查用于稳定整个公共交通系统数千英里轨道的大量紧固件。由于频繁的震颤加剧了机车车辆的定期磨损和高客流量,公交系统位于发生多次地震的火环,无法对其基础设施的安全性冒险。

通常,在其中一条线路的列车服务结束后,铁路运营商会派遣人工维护工程师对轨道进行人工目视检查,并检查紧固件是否松动。如果检测到轨道扣件松动或损坏,则必须在铁路线上的列车服务重新开始之前修复扣件。

由于在非运营时间对铁路轨道进行目视检查非常耗时,并且人为疲劳可能导致数据遗漏,因此公交系统决定部署人工智能边缘计算解决方案,该解决方案可以通过计算机视觉加速轨道紧固件检查。

更具体地说,交通运营商想要一个定制的人工智能推理模型,该模型具有用于轨道扣件系统的对象识别功能,可以在火车行驶时检测轨道扣件缺陷并在行程之间进行维护。

用于轨道紧固件检查的 AI 推理还要求边缘计算机具有强大的计算性能和视频数据存储扩展、紧凑的尺寸和安装在小型机柜中的无风扇设计、宽工作温度范围以及在机车车辆上使用的 EN 50155 合规性。

步是在火车车厢下方安装高分辨率摄像头,这使系统操作员能够在火车在服务时间内在轨道上运行时捕捉轨道紧固件的实时视频。然后将视频数据传输到车载边缘计算机,以进行图像处理和轨道紧固件缺陷的对象识别。

列车运营商选择了 Moxa 的 V2406C 系列轨道计算机,因为其体积小巧,配备英特尔酷睿 i7 处理器,可为运行经过训练的 AI 推理模型提供充足的计算能力。V2406C 还以低功耗运行,并具有 -40 至 70°C 的宽工作温度范围。

但同样重要的是,V2406C 支持英特尔 OpenVINO 工具套件,并具有两个用于英特尔 Movidius VPU 模块的 mPCIe 插槽,以加速图像识别计算和边缘 AI 推理。通过在运营时间内用实时 AI 视觉检查代替人工视觉检查,交通系统能够提高效率并降低维护费用。

我司产品广泛应用于数控机械 冶金,石油天然气,石油化工,

化工,造纸印刷,纺织印染,机械,电子制造,汽车制造,

塑胶机械,电力,水利,水处理/环保,市政工程,锅炉供暖,能源,输配电。

All trains, whether in an inter-city railway line or municipal mass transit system, run on metal tracks that need to remain upright and properly spaced according to a standard gauge at all times. If the tracks become uneven, trains could derail.

That’s why users always see some sort of support, known as railroad ties or ballasts, laid perpendicularly beneath the tracks. To ensure a smooth ride, railroad tracks need to be securely fastened to the ties by spikes, screws, or bolts.

Due to constant friction and vibration between fast-moving train wheels and the tracks, as well as damage from the natural environment, track fasteners degrade and break over time. Consequently, timely detection and repair of track fasteners is crucial to ensuring the safety of any railway line.

A large metropolitan railway in East Asia needed a more efficient way to inspect the vast number of fasteners used to stabilize thousands of miles of tracks throughout its entire mass transit system. Located in the Ring of Fire where many earthquakes occur, the transit system cannot take any chances on the safety of its infrastructure since constant tremors compound the regular wear and tear from rolling stock and high passenger traffic.

Usually, after train service ends on one of the lines, the railway operator dispatches human maintenance engineers to perform manual visual inspection of the tracks and check for loose fasteners. If a loose or damaged track fastener is detected, the fastener must be repaired before train service recommences on the railway line.

Since visual inspection of railway tracks during non-operating hours is time-consuming and human fatigue may lead to data omission, the transit system decided to deploy an AI edge computing solution that could accelerate track fastener inspection with computer vision.

More specifically, the transit operator wanted a customized AI inference model with object recognition for track fastening systems that could detect track fastener defects while the trains are moving and perform maintenance between journeys.

AI inferencing for track fastener inspection also requires the edge computer to have powerful computing performance and storage expansion for video data, compact size and fanless design for installation in small cabinets, wide operating temperature range, and EN 50155 compliance for use on rolling stock.

The first step was to install high-resolution cameras underneath the train carriages, which enabled the system operator to capture real-time video of track fasteners as trains run on the tracks during service hours. Video data is then transmitted to an onboard edge computer for image processing and object recognition of track fastener defects.

The train operator selected Moxa’s V2406C Series rail computer for its compact-size with an Intel Core i7 processor that provides ample computing power for running the trained AI inferencing model. The V2406C also runs on low power consumption and has a wide operating temperature range of -40 to 70°C.

Last but not least, the V2406C supports the Intel OpenVINO toolkit and features two mPCIe slots for Intel Movidius VPU modules to accelerate image recognition computations and edge AI inferencing. By replacing manual visual inspection with real-time AI visual inspection during operating hours, the transit system was able to improve efficiency and reduce maintenance expenses.

如果您有任何问题,请跟我们联系!

联系我们